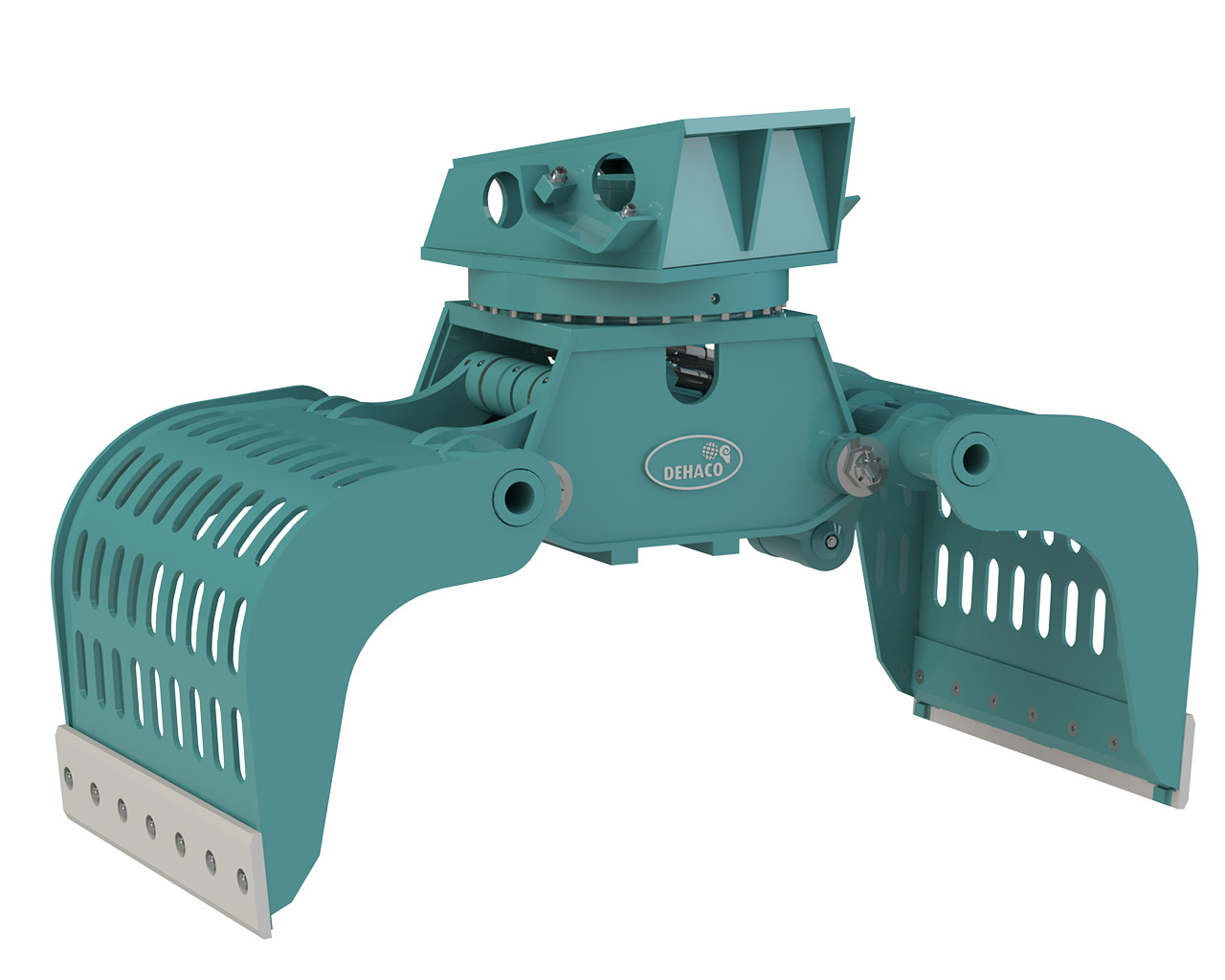

DSG Demolition- and sorting grabs with Rotation

Dehaco hydraulic demolition and sorting grabs can be used for a wide range of purposes, such as sorting and clearing a variety of materials, moving wood or construction materials.

The grabs are light, yet large in volume and highly manoeuvrable. The stationary cylinder(s) prevent the hydraulic hoses from moving, limiting damage to a minimum.

Features:

- Low maintenance because of stationary cylinders

- Solid frame

- 360° Rotation

- Cylinders with end damping

- Also available without turntable

DSG Demolition- and sorting grabs without Rotation

Dehaco hydraulic demolition and sorting grabs can be used for a wide range of purposes, such as sorting and clearing a variety of materials, moving wood or construction materials.

The grabs are light, yet large in volume and highly maneuverable. The stationary cylinder(s) prevent the hydraulic hoses from moving, limiting damage to a minimum.

Features:

- Low maintenance because of stationary cylinders

- Solid frame

- 360° Rotation

- Cylinders with end damping

- Also available without turntable

Timber Grab

Dehaco has a wide ranging series of hydraulic tree grapples for excavators in the 1.5 to 50 tonne weight class.

The tree grapples are characterised by a solid frame and a relatively low construction height due to the horizontal cylinders. The stationary cylinder prevents the hydraulic hoses from moving during opening and closing of the plates, limiting damage to a minimum.

Features:

- Low height because of horizontal cylinders

- Solid frame

- 360° Rotation

- Cylinders with end damping

- Dust seal in hinge

DEHACO HYDRAULIC BREAKER – IBEX GS-SERIES

The IBEX GS-series is comprised of 14 models, all equipped with a nitrogen accumulator and suitable for carriers from 0.8 to 55 tons. The IBEX GS-series is comprised of 14 models, all equipped with a nitrogen accumulator and suitable for carriers from 0.8 to 55 tons. The larger models in the GS-series (1200 – 4000) feature an accumulator to generate additional impact energy. The accumulator also reduces peak pressures from the hydraulic circuit, reducing recoil to the carrier and protecting the breaker. When desired the breakers are available with an open housing, the GO-series (Gas Open).

Breaking rocks, trenching, breaking concrete structures and buildings, asphalt and paving breaking, removing slag from blast furnaces and ladles, secondary rock breaking… When controlled force is necessary the IBEX hydraulic breakers from Dehaco are in a class of their own. Outstanding quality, extremely versatile, an amass of power and durability.

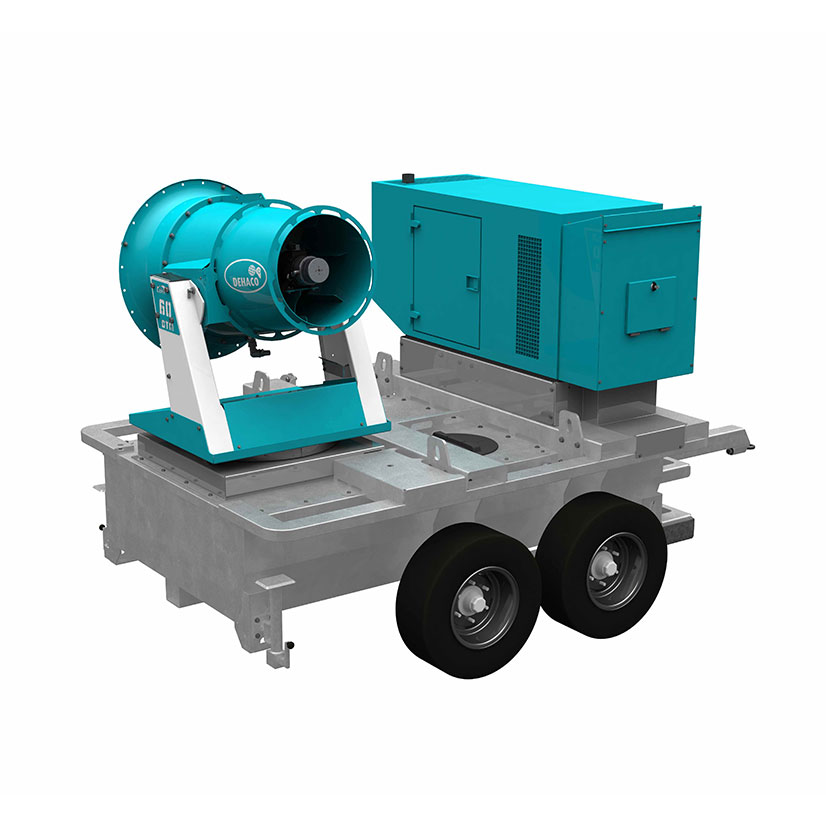

Tera 60 GTM/GTX

The GTM is independent of power and water supply. If required, the machine can also be connected to the local water supply.

Of course, the function of the Tera 60 GTM is based on a targeted distribution of a fine water spray to which dust particles adhere. Conventional nozzles require a lot of maintenance, as they get clogged up by lime particles in the water. The Tera 60 GTM deals with this problem once and for all, by using the Demto-Rotor® spray head in which the lime particles are unable to settle.

The size of the drops can be adjusted and, moreover, the Tera uses water sparingly, resulting in a maximum result with a low consumption!

The frame is built for heavy loads and has been provided with an integrated water tank. This water tank is placed low and has been provided with anti-motion baffles. This ensures the best possible weight distribution when moving the mobile unit. In this way, the load on the towing vehicle is as low as possible and a more stable road holding is ensured.

The Tera 60 GTM is also available without agriculture undercarriage and can be found in this brochure as the Tera 60 GTX. The GTX is just as complete as the GTM but comes without an agriculture undercarriage, drawbar and support legs.

Features:

- Water connection Storz C52

- Water consumption 500 – 4500 l/h

- Max. throw at position 3 “Power Boost 60 m

- Maximum throw at position 2 “Eco-Boost“ / 1 “Eco“.55 / 45 m

- Power consumption at position 3 “Power Boost12,0 (500 l/h) / 16,0 (4500 l/h)

- Power consumption at position 2 “Eco Boost8,0 (500 l/h) / 12,0 (4500 l/h)

- Power consumption at position 1 “Eco6,0 (500 l/h) / 10,0 (4500 l/h)

- Generator Dehaco ECO Power generator 15ME

- Power generator16 kVA 400V 60Hz 1800 RPM

- Fuel generator Diesel

- Electric rotation adjustment 0-240°

- Electric height adjustment (angle + 50 ° / -25 °)75°

Tera 60 Dust control unit

The Dehaco Tera, which is a champion in dust control, works by projecting a fine spray of water which binds to harmful lime scales. Conventional nozzles require a lot of maintenance because they are prone to clogging by lime particles in water uses. The Tera has no such problems in this area, thanks to the revolutionary Demto-Rotor spray head, which lime particles cannot adhere to.

The droplets size, water consumption and throw are all adjustable making the Tera suitable for every application.

The Tera can be mounted on a Dehaco agricultural chassis, or RDW-approved (road legal) single-axle or twin-axle trailer, depending on the weight of the unit and accessories.

Features:

- Weight 514 kg

- Water connection Storz C52

- Water consumption 500 – 4500 l/h

- Max. throw 60 m

- Ideal water supply pressure 3 bar

- Power consumption in position 3 (Power Boost) 12,0 kW (500l/h) / 16,0 kW (4500 l/h)

- Voltage 400 V

- Current 63 A

- Rotation adjustment 0 – 335°

Tera 25 Dust Control Unit 110V/230V

The Tera 25 is ideal for medium-sized demolition and renovation projects. The machine is easy to move and has a relatively large capacity. By using 230V and a Gardena® water connection, it can always be connected directly. The powerful Demto-Rotor produces a good spray. The revolutionary Demto-Rotor spray head that is used starting from the Tera 15, does away with all the disadvantages that conventional nozzles have, such as clogging as a result of lime particles in the water.

Features:

- Weight 90 kg

- Water connection Gardena

- Water consumption 0 – 120 l/h

- Max. throw 0 – 20 m

- Electrical supply 230V